Search filter

Filter

Reset

Downloads

- Installation drawing (953)

- Product data sheet (892)

- Tender texts (275)

- Installation instructions (245)

- 3D model (172)

- Product scale drawing (153)

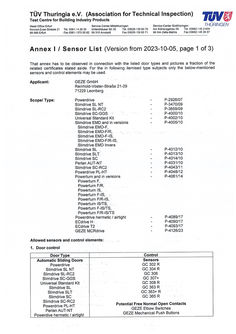

- Certificate (116)

- Declaration of conformity (83)

- Declarations of performance (83)

- Cable plan (59)

- Environmental declaration (49)

- Wiring diagram (45)

- User manual (34)

- Supplementary sheet (26)

- Product brochure (24)

- Flyer/folder (22)

- Declaration of incorporation (19)

- Inspection certificate (10)

- Type examination certificate (9)

- T&C / Data Protection (8)

- Software (5)

- Supplier information (4)

- Safety analysis (2)

- Evaluation/comment (1)

- Customer information (1)